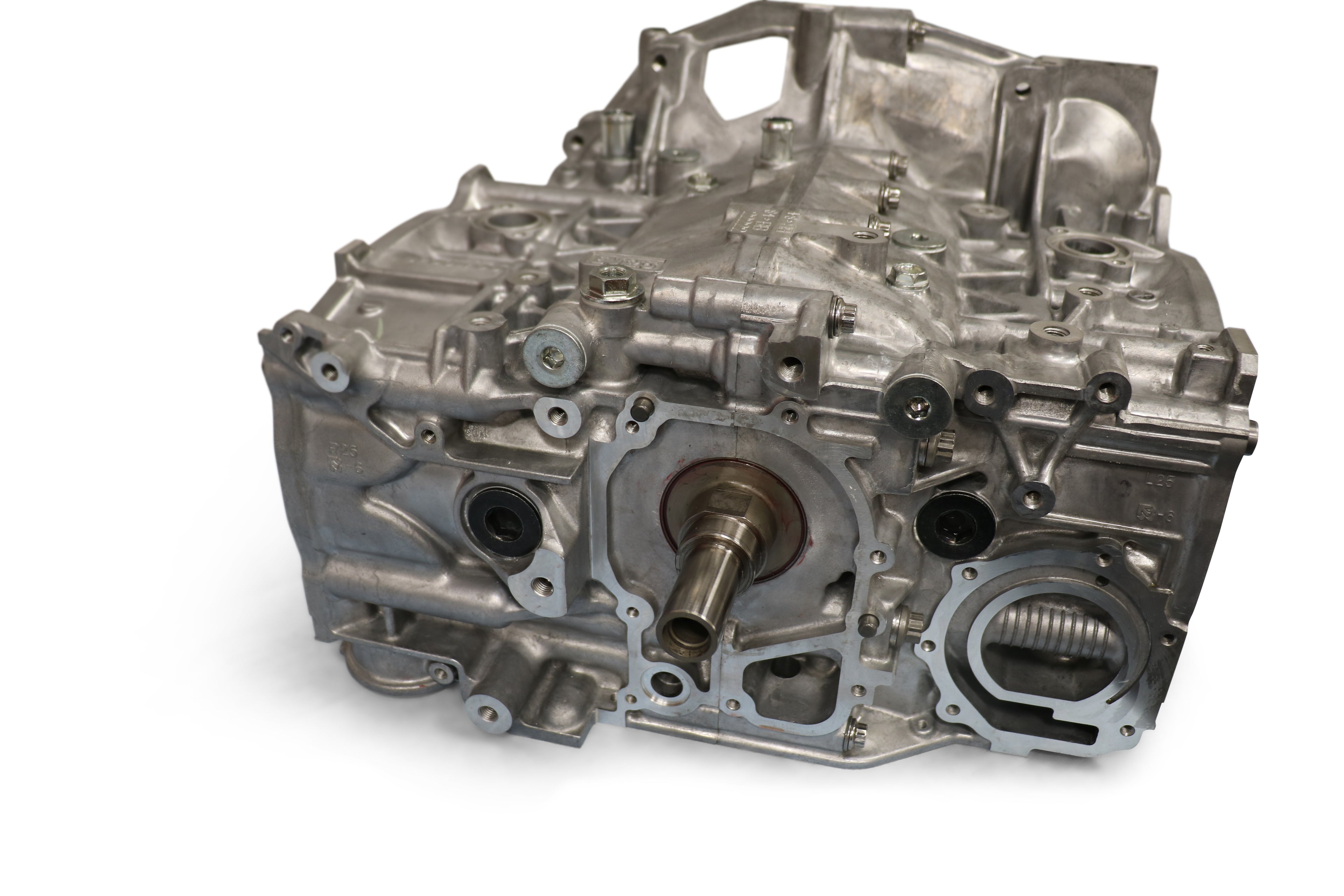

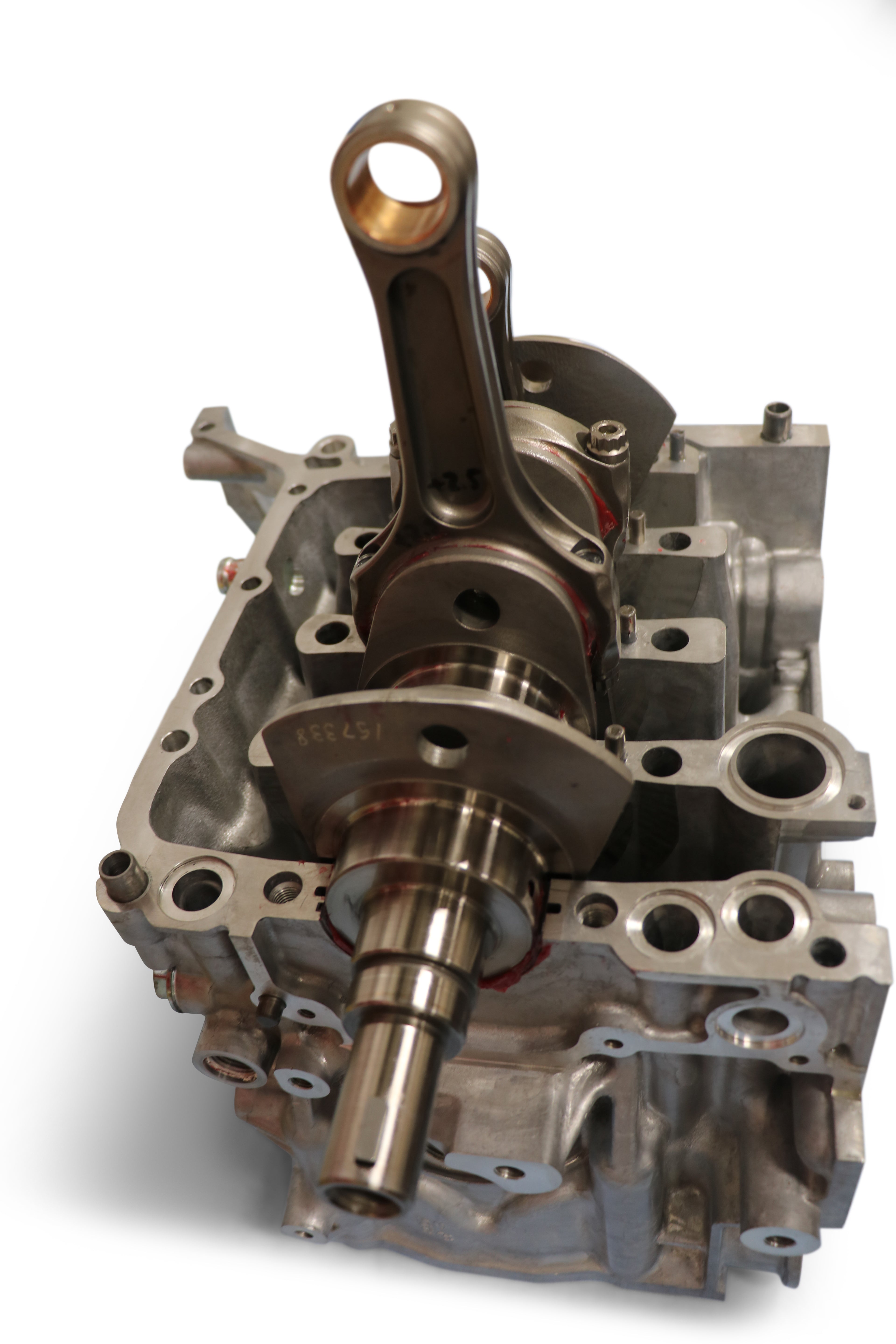

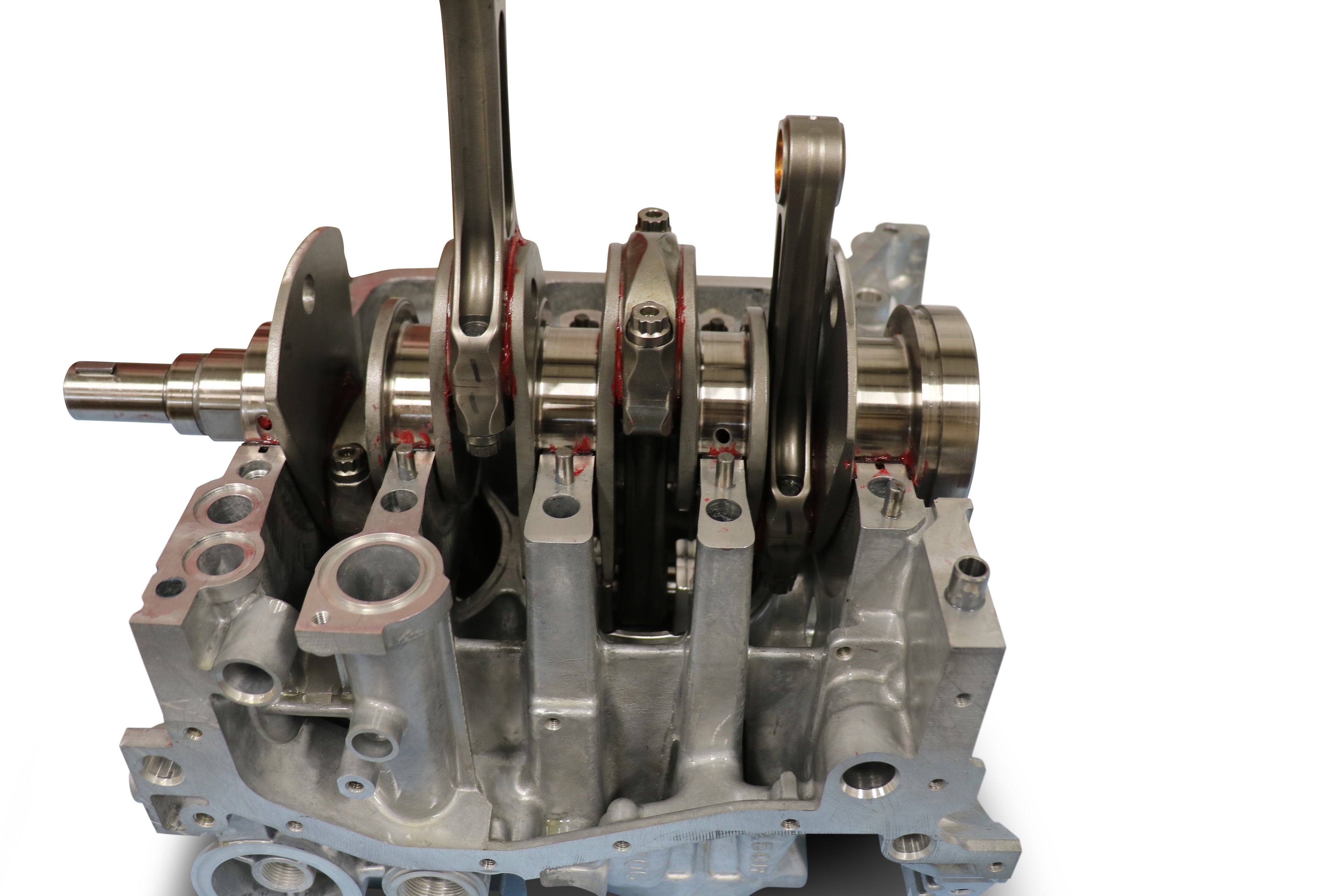

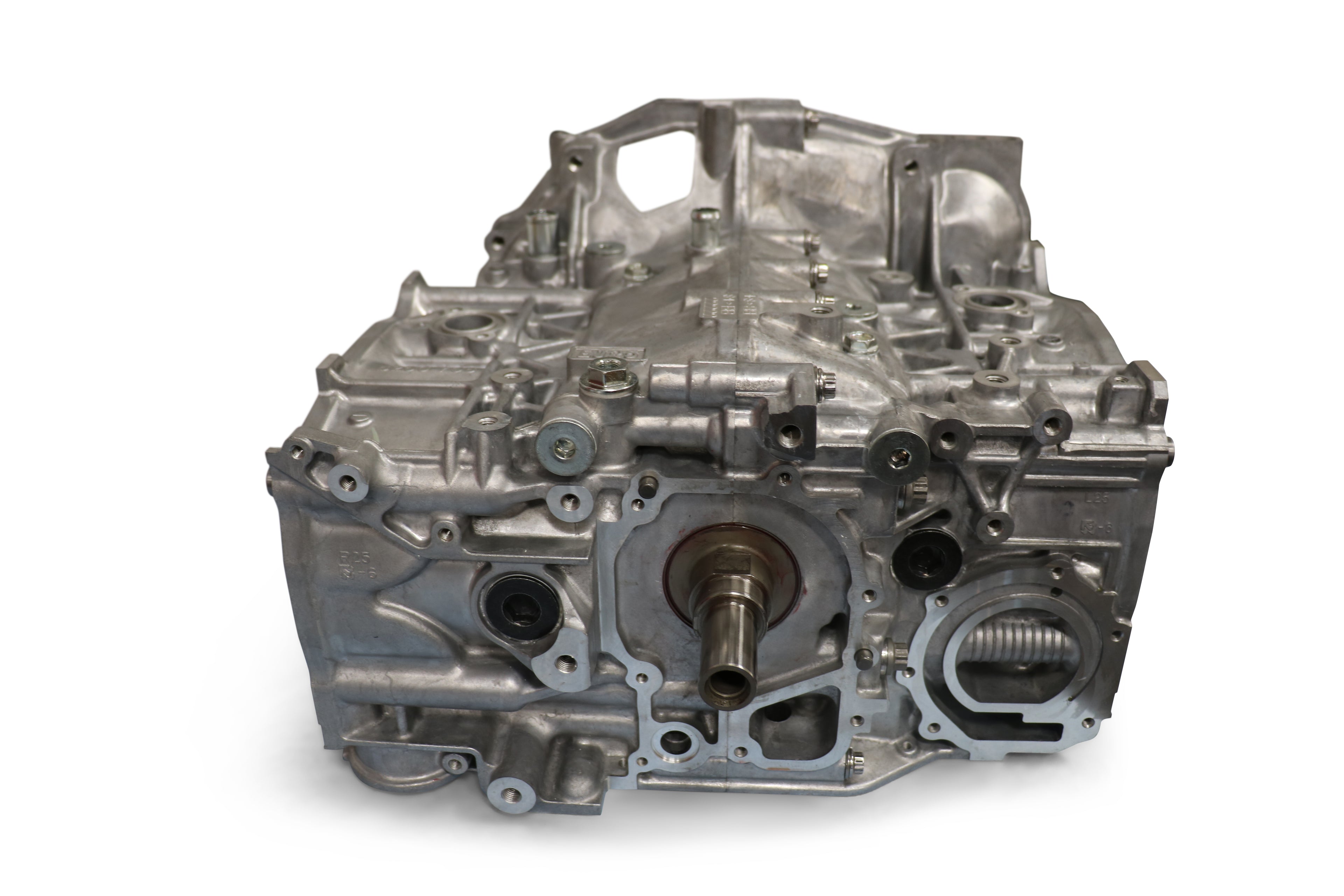

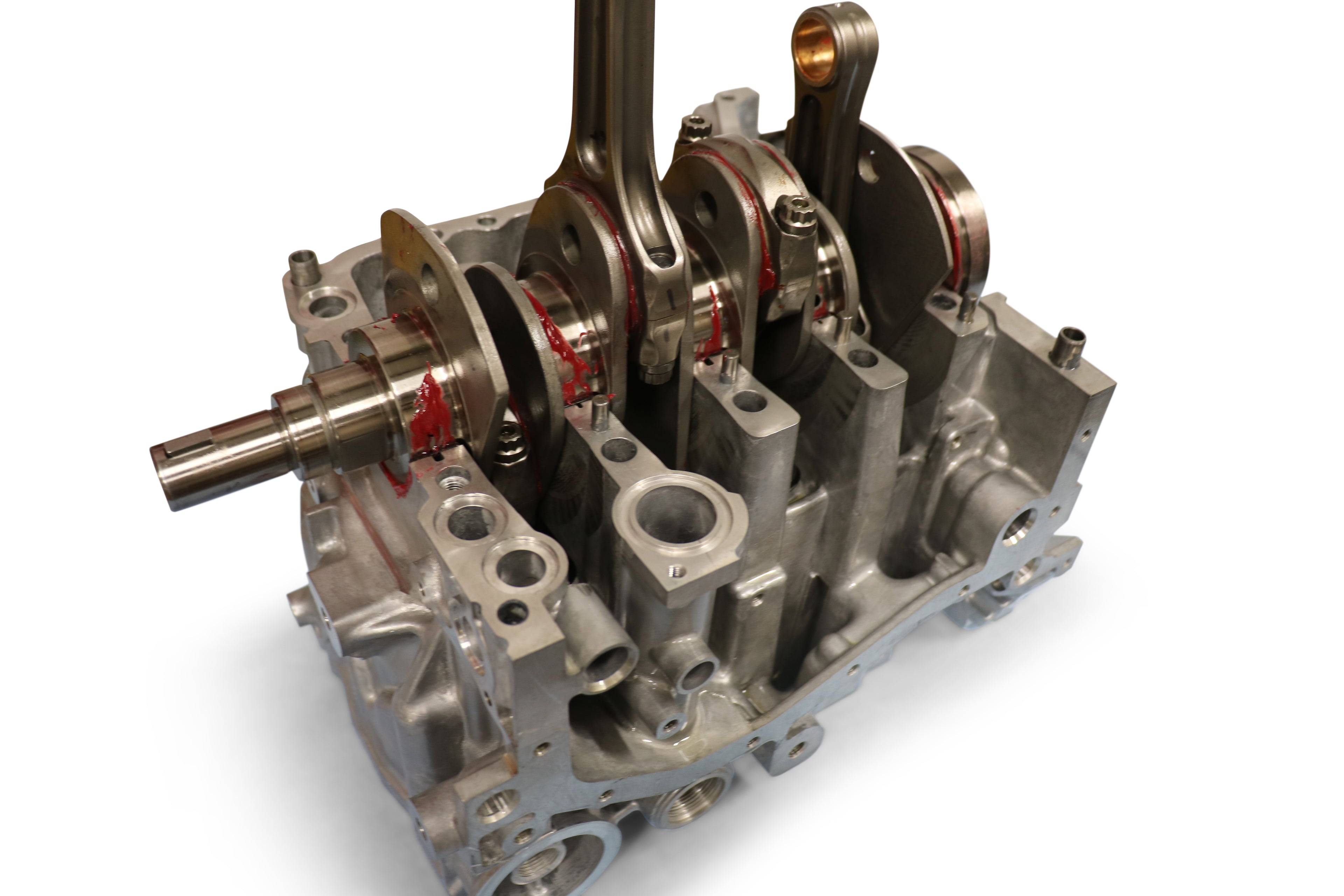

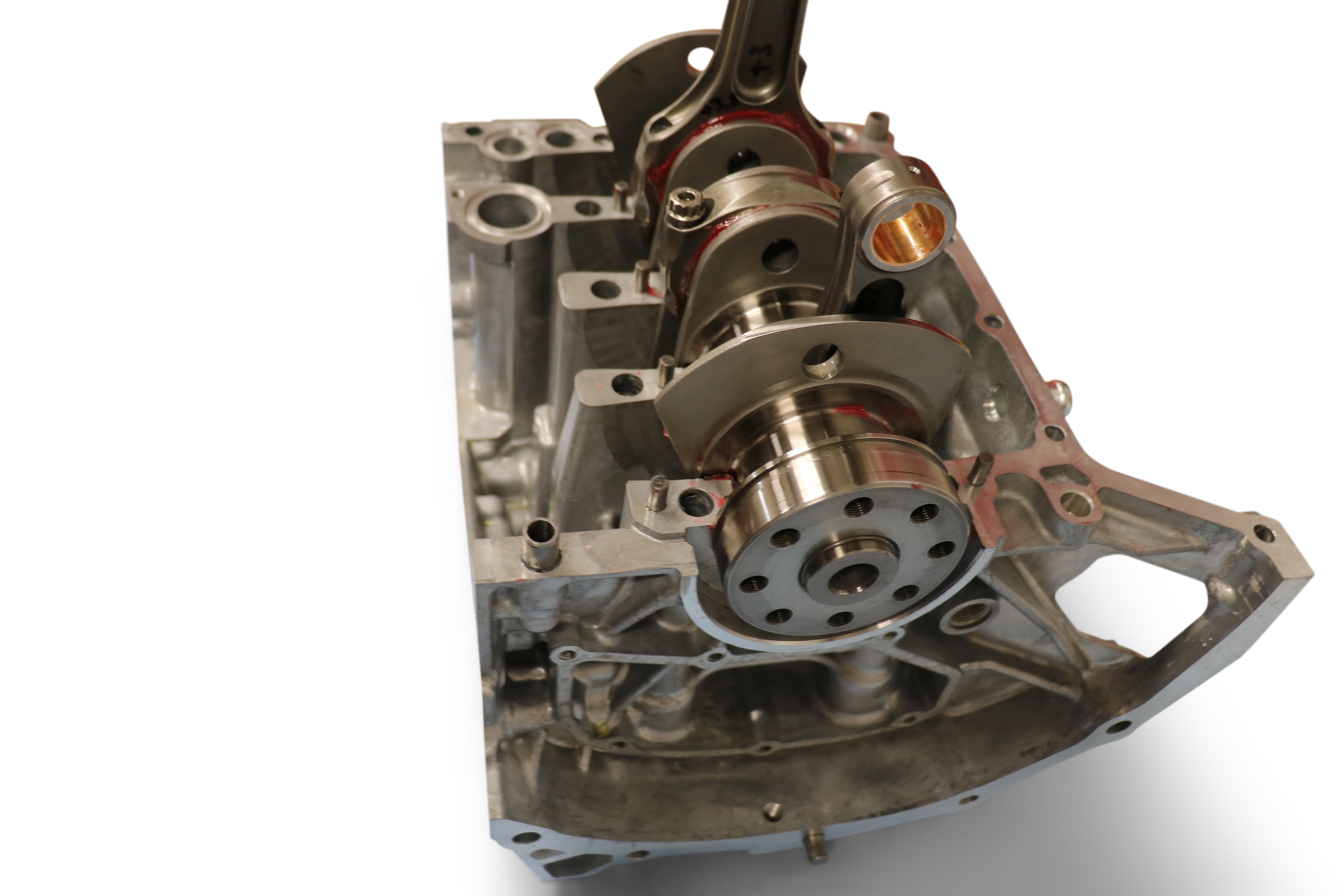

Our Stage 4 motor has been proven time and time again on and off the track. The Stage 4 short block utilizes our new closed deck mains and 11mm ARP case bolt upgrade as well as an upgraded set of I-beams. This allows you to reach the full potential of the stock forged and nitrided crankshaft. We have countless race hours on these engines as well as millions of street miles that prove you can have the best of both worlds. We balance and blueprint everything in these engines. Each piston is within ½ gram of each other, the rods are within ½ gram of each other on both the big end and the total weight. Each crank is sent off for balancing and comes in less than 1 gram. The time and resources spent on perfecting the clearances and balancing the rotating assembly is done on all of our engines.

Engine Highlights

- Core Charge of $500 is refunded for customer supplied case halves

- Designed for 40+psi, 950BHP and 8,500rpm

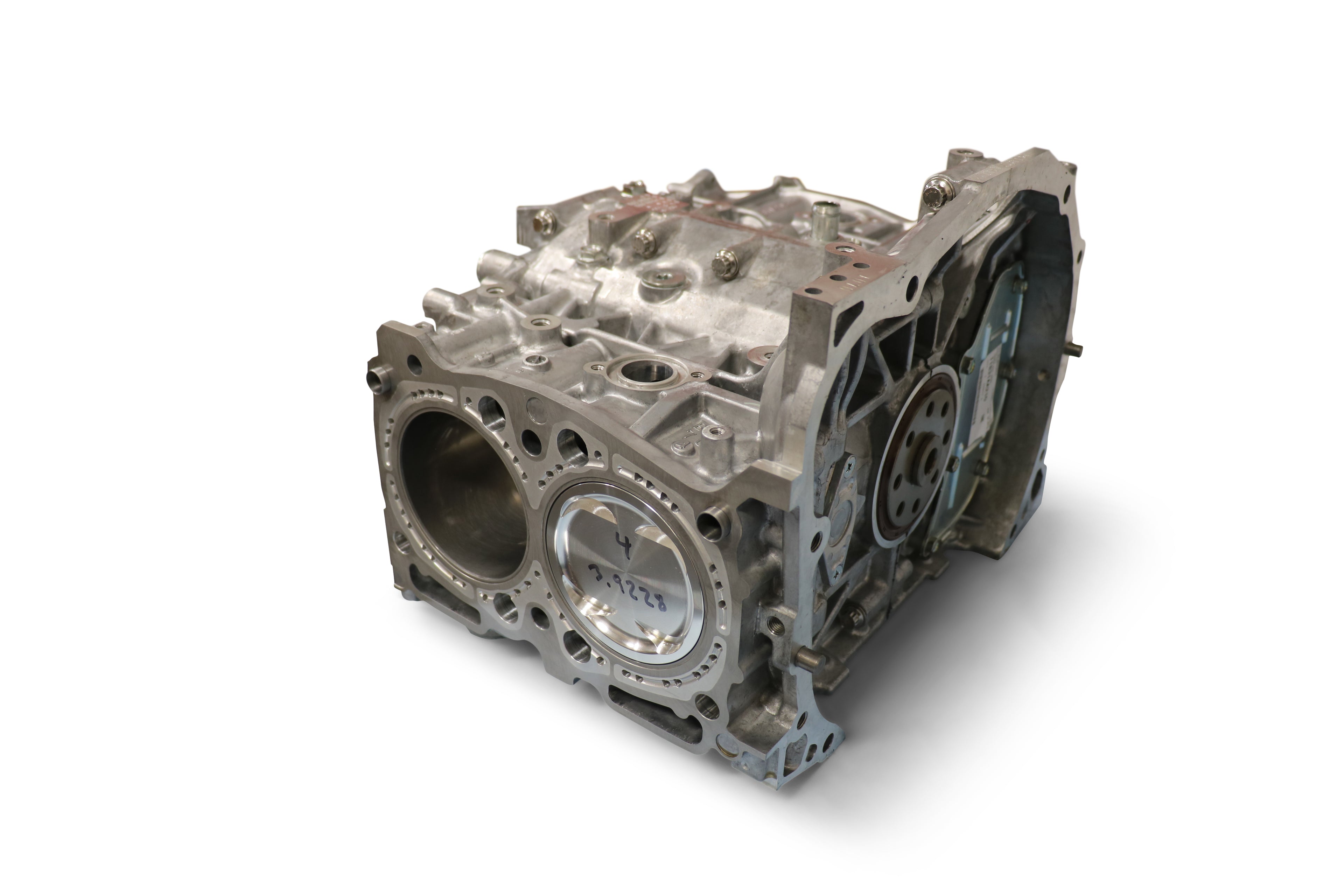

- Seasoned OEM Closed Deck Inserted Case Halves with Pinned Mains bored out to 99.75mm and align honed to exacting dimensions.

- The pistons are precisely measured and numbered for each bore. The bores are then honed to exactly the right size.

- We also align hone the mains to be within 0.0001” of nominal spec.

- NEW Closed Deck Mains

- NEW ARP 11mm Main Stud Kit

- CP Skirt and Top Coated P2P Spec Pistons

- Callies Ultra Rods w/ ARP625+ bolts

- Clevite Coated, ACL, or King Race Bearings for rods and mains.

- Brand New OEM Subaru Nitrided Crank

- Rear Cover, Oil Galley Plugs, and Wrist Pin Plugs come standard.

- Fire Ring Groove

- Machined for 14mm Forged Headstuds using our Flow Forming headstud machining (Read about the difference in our Resources tab).

Why Choose our Stage 4 Short Block Over the Competition? All machining, cleaning, and assembling are done by a degreed engineer. We provide a level of artisan craft in our engines only found in race teams and super cars. The experience we bring to our engine program is unparalleled in the industry. We blueprint the entire assembly of the motor to within .0002 of our specs,” Even though the H4 motor is inherently self- balancing, it is incredibly important to balance your motor to increase the life of your bearings. It is highly recommended to run a Fluidampr/ATI crank pulley or OEM. Do not run an aftermarket solid crank pulley. All of our inspection equipment is high quality, either from Starrett or Mitutoyo, and is sent off yearly for calibration to a qualified cal-lab.

Why do we use “Seasoned Cases for All Stage 2+ Short Blocks? This is a fascinating question in that it would seem that buying brand new cases would be best? Wrong! When new cases undergo racing extremes with temperature and stress, they tend to stress relieve or work harden. This may cause the deck surface to fluctuate or the main tunnels to change and get bigger or smaller (we are talking about 1/10,000’ths of an inch 0.0001”). Seasoned cases or “used cases” have undergone these fluctuations from numerous hot/cold cycles and millions of stress cycles. Because of this, we prefer to take these seasoned engines and re-machine them to our specifications, as they don’t change under loaded conditions. There are decades of research and thousands of white papers written on this phenomenon.

Break in Procedure is Found HERE

Warranty Information is Found HERE